Meet ZerLux Hungary on international Petroleum Technology Conference in Dhahran, Kingdom of Saudi Arabia.

Find us at Saudi Aramco's booth!

Main Application Areas

Changing the Game…

ZerLux Hungary Ltd. is an ISO:9001 certified, independent and privately owned R&D-based manufacturer company. With global experience in completing 120+ successful downhole camera jobs, we serve onshore and offshore operations for Oil & Gas and Geothermal Industry with our range of specialized in-house manufactured tool.

Zerlux announces that tools from our OptEye Downhole Camera Family is available for SALE!

- As Service Provider, “Own OptEye tools and forget about revenue sharing”

- As Operator, “Own OptEye tools and become independent from third party service. Reduce overall wait time and your operational cost”

- Get trained on OptEye tools from our experts. We believe “Its downhole camera, not a rocket science”

- With our global expertise, “Get personalized support for Running and Well-Cleanout Procedure”

- Reach us for “Big saving by Owning and Investing in our OptEye Downhole Cameras for your daily operations”

High Temperature

Fiber Optic

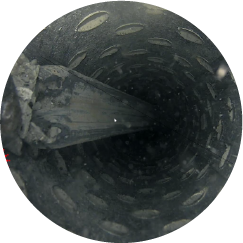

Fiber Optic downhole camera technology is the most advanced, highest real-time resolution downhole visualization tool that can provide 60 frame per second, full HD quality video from a high pressure/high temperature environment.

Fiber Camera can run on Fiber Optic or Hybrid Cable..

Read more

Hybrid

Downhole Camera

Hybrid camera technology can operate both on standard Electric Line and Slickline cable. The Hybrid camera system combines the practical advantages of real-time visualization and memory recorded modes at the same time offering near Zero NPT from loss in connection.

Hybrid cameras can run on Electric line and Slickline cable.

Read more

Coiled Tubing

Lens Cleaning

Coiled Tubing operations frequently require visual feedback in order to avoid misruns. CTU Camera are designed for CT applications, having robust housing and lens cleaning options. The pumped fluid can jet on the camera lens in order to provide good visibility even in harsh environmental conditions.

Read more

High Temperature

Memory

Memory gauge investigations are one of the most widely used technologies, easy to deploy, providing valuable information from the wellbore. Zerlux offers full HD resolution, 60 fps video quality recording even from 180°C wells, providing quick and user friendly data recording, and easy to merge software support.

Read more

Who We Worked With…

Who We Worked For…

-