Laser Pipe Cutter

Technology is ready for Surface Integrity Test in practice

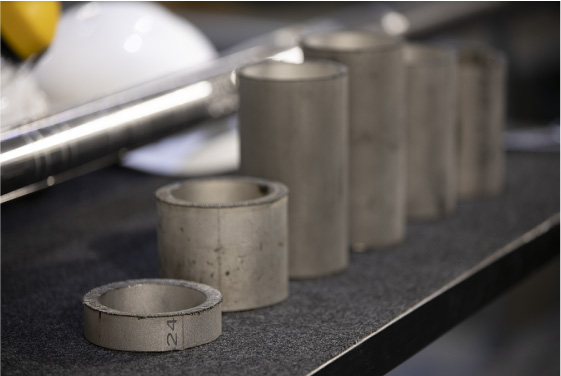

Quick and precise cutting with a clean, straight surface. Rigid and fragile debris can be easily removed. A controlled nitrogen flow is responsible to keep clean continuously the cutting surface.

Laser Single-Pipe Cutter

Laser Single-Pipe Cutting technology is developed to offer to our clients a precise, quick, clean and controlled downhole cutting of any kind of casing pipes, production tubing and drill pipes. I spite of any commercially available pipe cutter technologies (e.g. chemical, explosive, mechanical, RCT, etc.) our improved laser cutting technology is full-controlled and provides a real-time feedback about the whole cutting progress and adequately about the successful result of the pipe-cut process. Thanks to advanced fiber optic technology and the online control, the cutting tool could modify the depth of the cutting even during the operation in order to prevent any damage of outer tubing/casing.

Our technology uses no hazardous material, provides a safe, quick and cost-effective solution for any kind downhole pipe-cuttings.

The laser cutting tool uses a high-capacity (multi kW) laser energy generated by the own-developed surface equipment and transported by strongly armored high capacity fiber optic cable to the downhole assembly in the well.

Main applications

Cutting any size and quality production tubing, casing and drill pipe

Benefits

- Safe

- Quick

- Precise

- Controlled

- Immediate result

- No toolstrick

- Cost effective

- No hazardous material

- No damage on tubing behind

- Works in all kind of wellbore fluids

- All kind of tubing quality can be cut

- No need multi run-in-hole processes

- Real-time feedback about the success of the cutting

Interested in this new technology? Contact us!

Armored Fiber Optic Cable

Fiber Optic technology is widely used in the Telco industry and nowadays has become quite current in the Oil & Gas segment as well. This high-tech technology is also used for real-time logging and monitoring acoustic (DAS-VSP), temperature (DTS), pressure (DPS) log data from the wells.

Above the high capacity of data transport Fiber Optic cables are also able to transmit even high capability (multi kW) laser power to a downhole environment safely with very small energy losses to use in different downhole operations.

| Armored Fiber Optics Cable | ||

|---|---|---|

| Cable OD | 11.18mm | 0.44" |

| Breaking Strength | 80.1kN | |

| Temperature Rating | 150°C | 300°F |

| Pressure Rating | 690bar | 10 000psi |

Zerlux provides also a rent service of fiber optic cable to customers in case of needs.

Laser power is generated in the surface equipment

Zerlux developed custom designed laser engines are responsible for generating suitable, multi kW output laser power. Recently, Zerlux put 2 x 8 kW laser engines into operation. Laser engines are placed in a special Laser Cabinet in order to be transportable easily and safe. Laser Cabinets are complete systems including power supply and chiller.

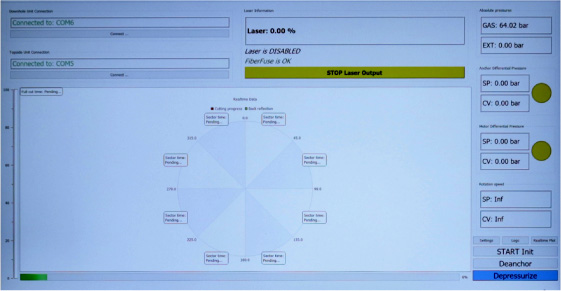

Automatized Software

In order to continuously monitor the cutting progress Zerlux developed a special user-friendly software to keep all parameters controlled and safe during cutting. Pre-programmed, automatic processes are responsible for the cutting although all cutting parameters can be modified real-time by the operator as well.

Uniquely specified cutting parameters

The cutting period is extremely quick, usually less than 2 minutes in case of standard tubing size, while the cut surface is clear and straight. The pressure vessel contains a nitrogen, which flow provides a clear path and space for the cutter laser light, therefore the Zerlux's tool is able to be used in any kinds of typical wellbore fluids. The real-time spectroscopy can prevent any damage on the casing behind the targeted pipe.

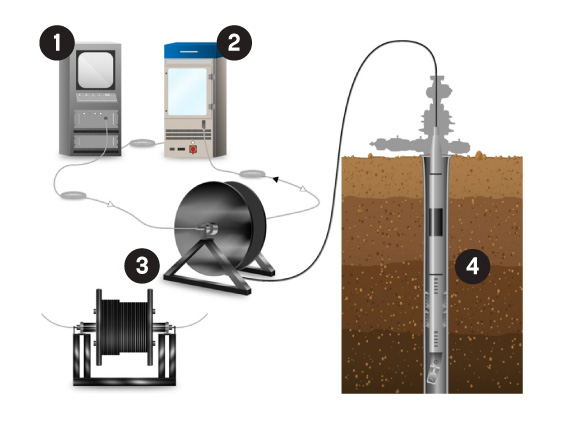

How does it work?

- Our custom designed laser engines within a special laser cabinet generate la high capability laser power on the surface equipment for different operations in the wellbore.

- Automatized, user-friendly software monitor and control the downhole procedure while providing a real-time feedback about the progress.

- Armored fiber optic cable transports the generated laser energy to the downhole BHA. Special fibers ensure real-time monitoring of the cutting and assist to avoid any damage on the casing behind the targeted pipe.

- The complete BHA contains a rotating laser cutter head, downhole motor, knuckle joint, anchoring system, special pressure vessels, electronics and telemetry in order to perform precise, quick and controlled cutting on tubing with different OD range and wall thickness.